AUO offers exceptionally stable and highly reliable customized modules suitable for various environments and has improved field applications of solar power generation with additional diversity

In response to the government's target of achieving 20GW in PV by 2025 and market demand trending towards high-performance products, implementing a highly stable and reliable PV plant is the foremost consideration of every customer. Selecting the key component for "modules" is critical for PV plants. AUO's mono-crystalline modules with multi-busbar half-cut technology offer exceptional power generation performance that maintains stable operations for PV plants. Their high weather resistance is suitable for harsh environments and can satisfy customers' diverse project requirements. In response to the international trend of Nearly Zero Energy Buildings (nZEBs) and various renewable energy applications, AUO has developed PV modules that can be attached to or integrated into buildings. Additionally, module designs can be customized to effectively utilize the surface of the building facade and increase the diversity of field applications. Products include the vivid and aesthetic SunBello module, the flexible and lightweight SunCurva module, and the quick-and-easy-installed SunSteel module, all of which offer the 5 major benefits of aesthetics, energy, carbon reduction, thermal insulation, and easy installation.

Learn more : AUO Energy Business

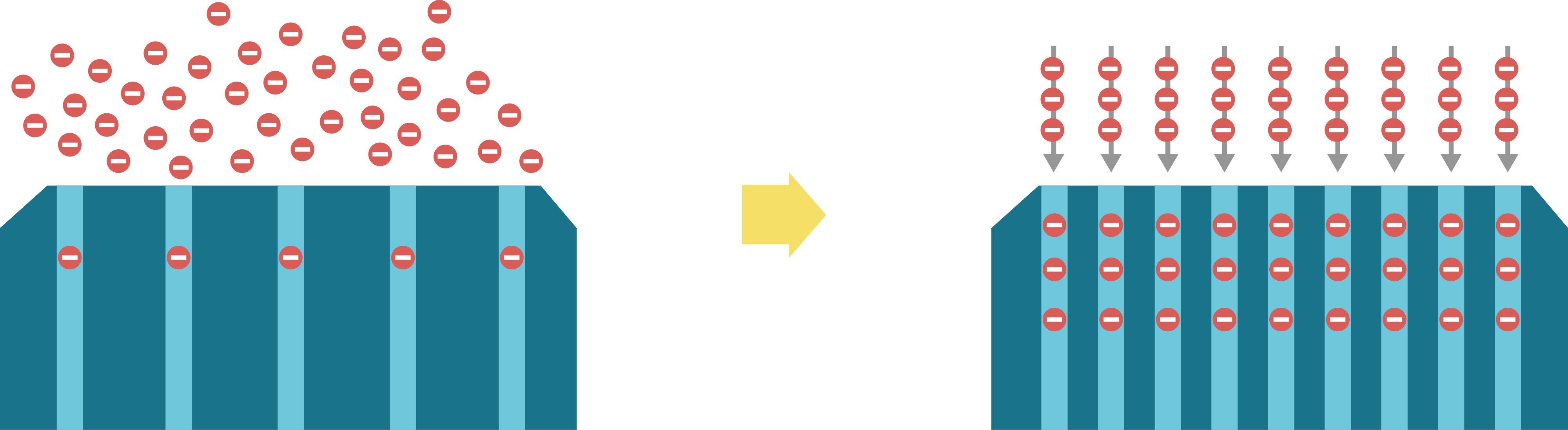

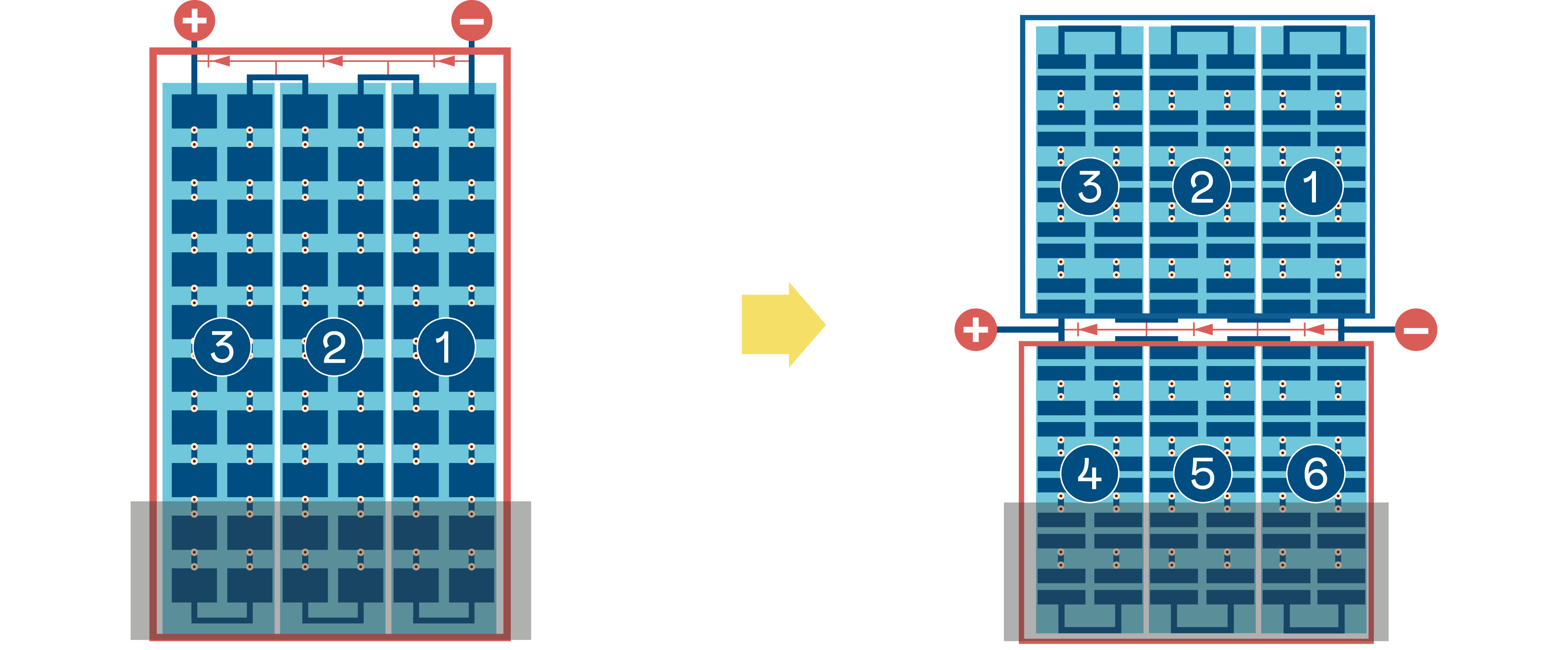

MBB HCC is next-gen technology that optimizes the design structure of solar batteries, allowing solar modules to maintain stable output performance over extended periods and enhance power generation performance and reliability.

-

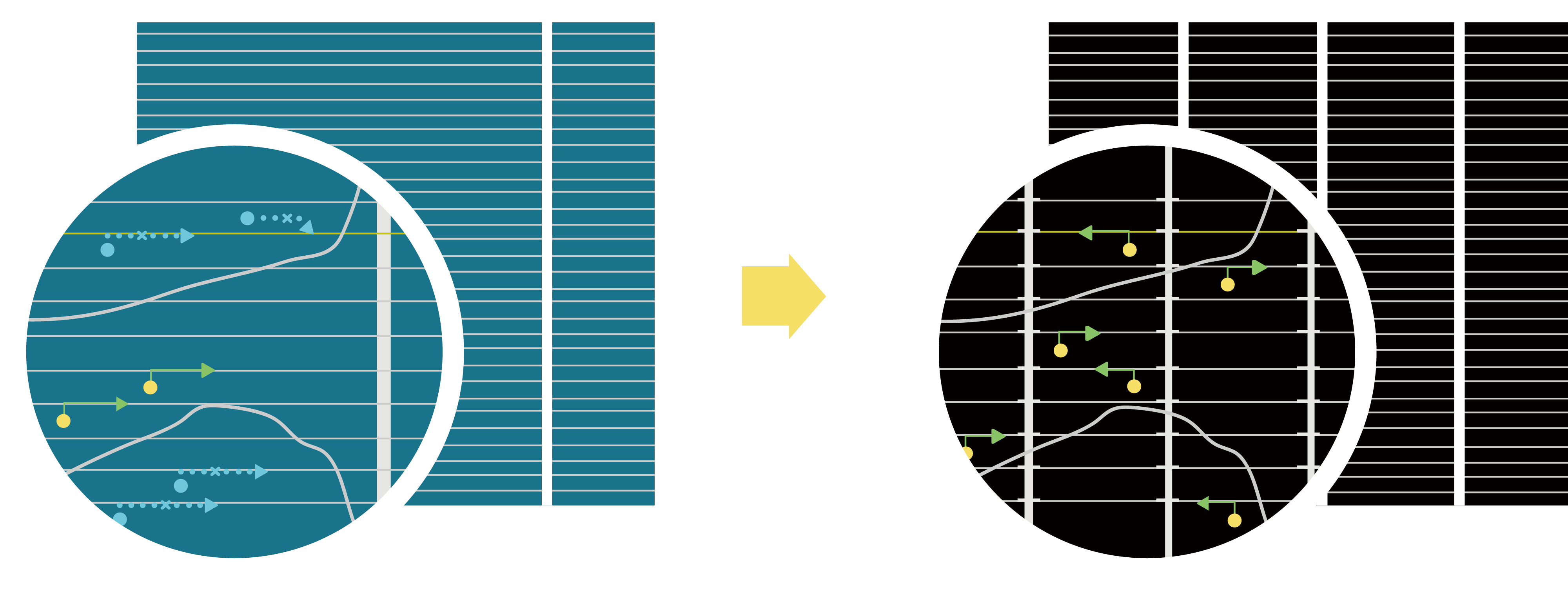

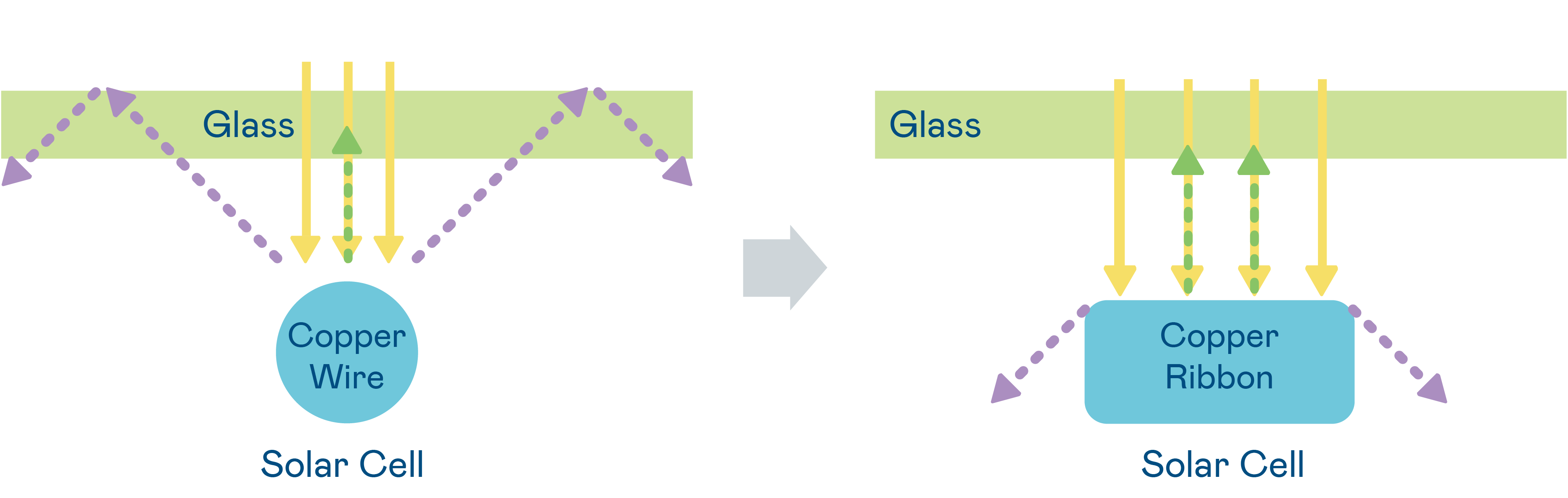

The solar cell utilizes multiple strands of copper wire to form shorter current paths and improve current collection efficiency; the round copper wires increase the amount of light incident to the battery compared to traditional flat copper ribbons.

-

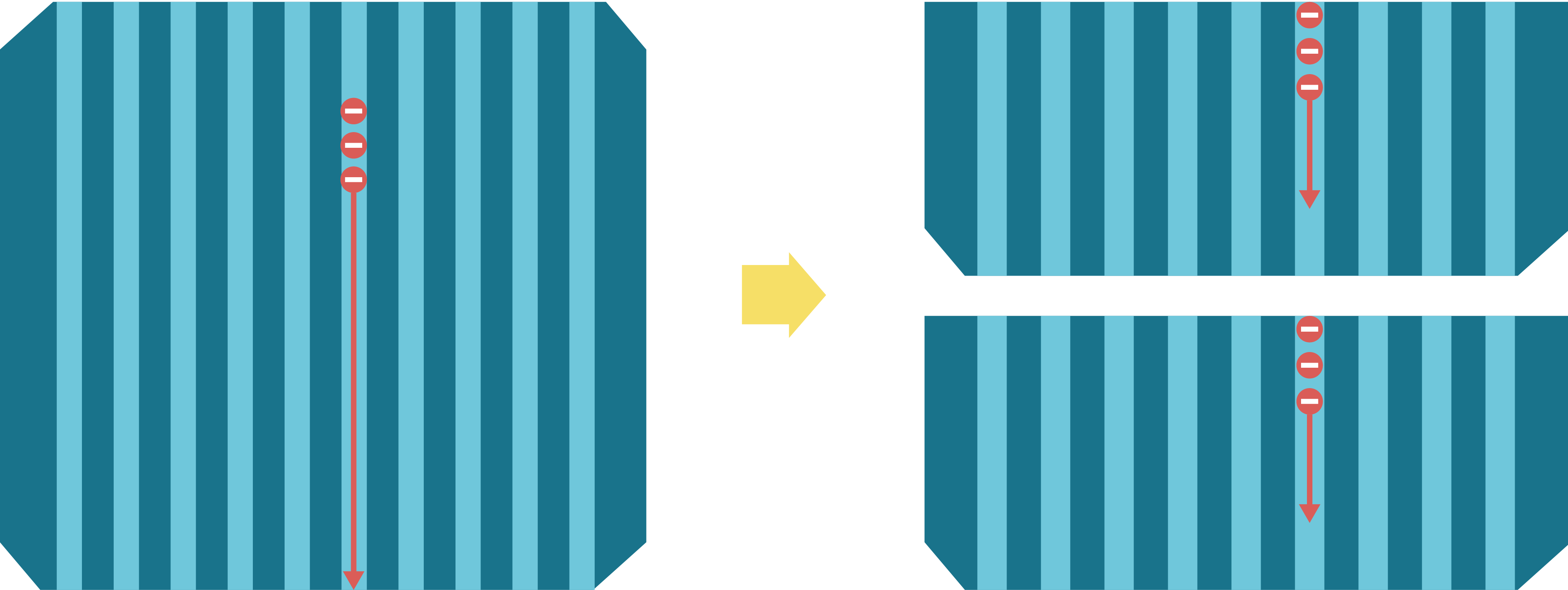

Integration with half cut battery cell reduces the impact of shading, minimizes the impacts in micro-cracks, and decreases loss due to resistance, further improving the module's power efficiency.

-

The multi-busbar structure effectively decreases the impact of external force on batteries and restricts the scope of micro-cracks, preventing the expansion of damage from the current distribution.

-

Special packaging materials and wind-resistant aluminum frames are utilized for up to 12 times more salt mist resistance and 40% more moisture exclusion. They are suitable for applications in ocean (water) territories and harsh environments with strong winds, high levels of moisture, and high levels of salt mist. The modules have passed dynamic mechanical loading tests 4 times greater than the IEC requirement.

Multi-busbar reduces current loss

Reduced shading effectMulti-busbar forms shorter current path

(Impact of micro cracks on power generation is reduced)

The amount of incident light is increased with new welding wire

Reduced loss from electrical resistance

Reduced shading effect

The implementation of special packaging materials and wind-resistant aluminum frames offers resistance to high humidity levels, salt- mist, and strong winds, making them suitable for harsh environments.

-

High weather resistance

The special packaging materials and wind-resistant aluminum frame design offer salt mist resistance 12 times greater than standard modules and 40% more moisture exclusion. It allows for stable operation over extended periods, even when deployed along coasts or in harsh environments with strong winds, high humidity levels, and high salt mist levels.

-

Highly reliable modules

Implementing modules with higher durability increases power performance and reliability, greatly decreasing the general operating costs of PV plants.

-

High stability

Optimized solar energy cell designs increase the current collection's efficiency, reduce micro-cracks, and allow solar modules to provide stable long-term output performance, increasing operational efficiency.

Application

-

Rooftop

To overcome rooftop spatial constraints, use our high-performance module solutions to obtain more power from limited installation surface areas and increase revenue.

-

Ground-mounted

Sites, where ground-mounted modules are, usually in harsher environments than general sites. Should carefully select modules that are highly reliable and highly stable in power generation performance to maintain long-term stable power plant operations.

-

Floating

Sites, where floating solar systems are used are usually detention basins, reservoirs, and ponds. Due to the high humidity of water environments, the construction area being determined by water conditions, and the surface area of floating platforms, high-performance modules capable of resisting harsh environments while maximizing power generation are recommended.

-

包括的なサービスについては、お問い合わせください。